Shopping for groceries may constitute retail therapy sometimes, for some people, but generally, it’s a chore. It’s a chore that involves spending valuable time at supermarkets that know how to work on human psychology to induce people to buy items they don’t really need. Interior design in supermarkets is geared towards optimising this social reality. Retailers understand that the layout of supermarkets and the placement of different items can impact consumer spending considerably. For store design & planning team, outsourcing technical services, such as architectural CAD drafting services and BIM consulting services to offshore partners has proven to be an efficient and cost-effective solution to developing supermarket interior design that can set the supermarket’s tone and increase profits.

The designing of a supermarket’s layout requires insight into basic human psychology. Designers spend time and effort to create a supermarket layout that will influence customer spending. The flow, merchandise placement and ambience of the store layout will affect the behaviour of customers. Retailers can assess their proposed revenue by looking at these layouts, resulting in informed decisions regarding the pros and cons of their mix of merchandise and where to place them.

Some of the proven features of customer behaviour and how they can be used to determine layout plans are as follows:

- Longer stay in a store results in a higher chance that something will be bought. So, retailers try to delay the customer’s exit.

- Store traffic will be affected by the placement of escalators, fixtures and department placement.

- Necessities, such as milk and eggs, are frequently located in the back of the supermarket, so that customers must pass the maximum number of other merchandises to get to them, thus potentially enticing an impulse buy.

Other interior design features retailers use to provoke additional sales include the following:

- Grouping

Merchandise is grouped in categories, so that when customers are looking to buy a specific product, they will discover other related products, which they may or may not require. Salsa and chips, breads and sandwich spreads and detergents and rubber gloves are placed adjacent to each other.

This also involves placing similar brands close together to ensure that customers who are loyal to a brand are able to find the one they want, resulting in additional cross-category or cross-brand sales.

- Layouts for Theft Prevention

Displays or sections with small items that can be easily stolen are typically placed near security support, such as near the exit, before the check-out counter – somewhere that has extra security personnel or that involves a barrier for an extra physical movement, so that it is not easy to flee from the premises.

- Displays that Encourage Positive Vibes

When customers are feeling good and comfortable, they feel good about their purchases. Layout design can set the mood through merchandise placement, aisle space and colours of fixtures and walls.

- Shelf Height

Fixtures that are so tall that they block visibility has been known to cause anxiety, since shoppers must travel through every aisle. When the layout is open, anxiety is reduced, inducing shoppers to linger and make more purchases.

Why is shelf positioning so important to retail interior design?

Supermarket sales are dictated by positioning, the importance of which determines ‘shelf rent’ (cost of certain shelf positions for each product) in many cases. This is because customers need to easily view a product to buy it. A product which is hidden behind other products or on lower/higher shelves than the range of space that is easy on the eye may not sell as much.

Factors that influence where products sit on the shelf include the following:

- Increasing Profits

A product’s ‘selling’ potential influences its shelf position. Eye-level on a shelf is considered prime real estate in a supermarket. High-demand items, such as food staples, with high sales potential will be placed at eye level to ensure that as many units as possible are sold. Branded products are often placed on lower shelves to make way for in-store brands and special offers on eye-level shelves.

- Targeting Customers

Understanding the target customers of different products is important. The maximum focus is on products at eye level, but some target consumers are of a different height. Children will notice, crave and insist on buying products at their eye and hand level, which means that toys, stuffed animals, most junk food and fizzy drinks may sell better from lower shelves. Products that appeal to adults will find space on higher shelves.

The supermarket has slowly evolved into the market square of old. Open plans, open ceilings and clear store graphics contribute to an open market feel.

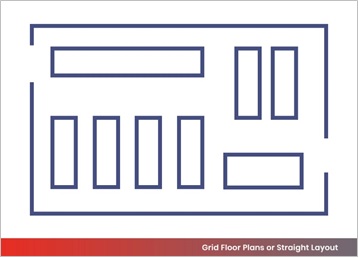

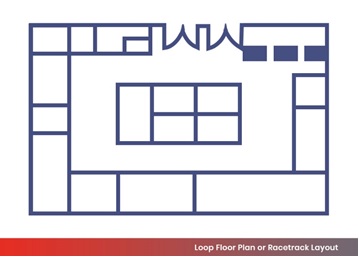

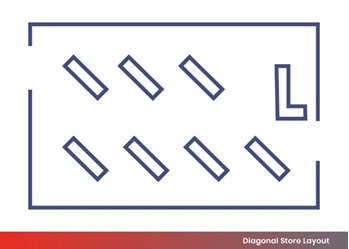

How does a supermarket’s floor layout affect sales?

- When customers are directed by a layout plan to walk to the back of the supermarket, they will inevitably see many other items on the way. At some point on their walk, they will be enticed to pick up certain products they had not planned for or were not aware of, increasing sales for the supermarket.

- Clever supermarket owners will consciously position high-volume products, such as milk and bread, at opposite sides of the supermarket floor, so as to maximise the consumer’s exposure to merchandise placed between them. In-store bakeries will be placed in a central position, since the aroma of freshly baked items will encourage impulse buying by hungry customers.

- Putting fresh produce, such as fruits and vegetables, near entrances gives rise to a few simple benefits. During the day, the natural light that falls on fruits and vegetables makes them look better and naturally fresh. As they are seen first, this produce will be picked up quickly and by a larger percentage of visitors, ensuring that most of such perishable items are not left behind. Since supermarket owners are cognisant of how people want healthy food, a spacious produce area will encourage customers to linger and spend more on fruits and vegetables.

- Flowers also brighten up and beautify the entrance. Seeing something beautiful and smelling the floral aromas enhances the feeling of freshness. Placing them close to the fruit and vegetable section increases the freshness quotient of both.

- Cooking ingredients and canned goods along with other general merchandise are usually placed in the central aisles to lure customers deeper inside the supermarket, so that they are exposed to nonessential goods while getting there.

- Eggs, meat and dairy products are ideally lined up on the back wall of the supermarket space to make sure people see a variety of products that may facilitate ‘impulse buys’. Traditional ‘impulse buys’, such as magazines, mints and chocolate bars are placed at the checkout counter, which makes waiting in line a perfect opportunity for that ‘final sell’.

- Sampling stations, special live display counters and cooking demonstrations typically line one of the outside walls to slow customers down while they are exposed to other products.

Increasingly, supermarkets are contributing to initiating and sustaining social connections. Parisian supermarkets are introducing areas where patrons can enjoy wine and warm food with friends. American supermarkets are trying to incorporate sections where customers can sip cocktails. Delicatessens and cafés should ideally be located at one of the front corners, so that people have the option of eating first, relaxing and then shopping, making it more likely that they will buy more items.

Enabling the development of 3D design in décor manufacturing, lighting and interior design involves the use of 3D modelling software, lighting test labs and a design resource library. Lighting tests can help predict the effects of bright, fluorescent lights or soft mood lighting on triggering a need to buy in customers. Such 3D previews help visualise the supermarket and its effect on the shoppers inside.

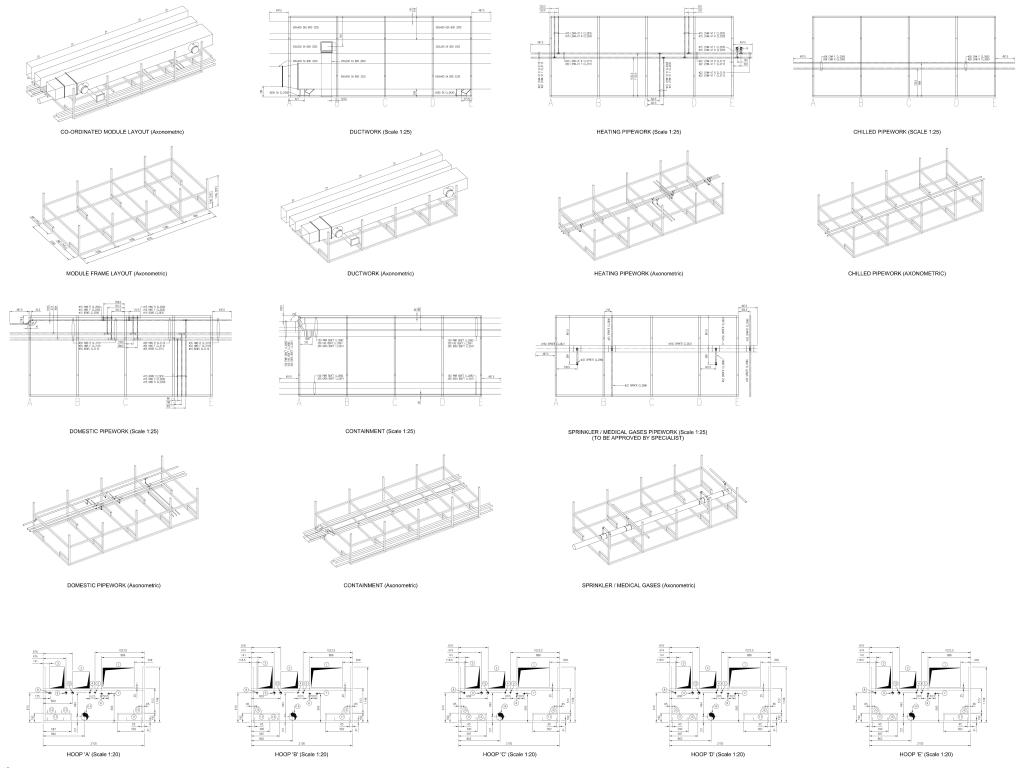

Many firms in Western countries are moving towards outsourcing architectural drafting services, including the delivery of retail construction drawings. High-quality retail design drawings and architectural BIM services can help develop designs with detailed dimensional accuracy, that can be digitised and modelled, so that revisions and changes can be made quickly and easily. Offshore companies provide architectural CAD drafting services that are precise, cost-effective and that enable the 3D visualisation of a supermarket space, plan, layout or strategy, which ultimately helps supermarkets increase their profits.